ICP-RIE Plasma Etching System RIE-400iPC

Space-saving Production System

Description

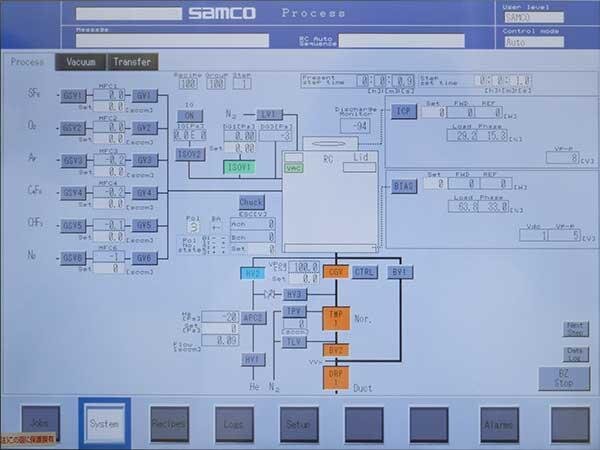

The RIE-400iPC cassette loading ICP-RIE plasma etching system utilises high-density inductively coupled plasma (ICP) to achieve precise etching. Designed for wafers up to 100 mm (4 inch), the system features an advanced ICP source, temperature-controlled electrode, and a high-flow exhaust system, all within a compact, space-saving design. This system provides exceptional process repeatability and stability, ensuring excellent efficiency for a wide range of etching applications, including GaN, GaAs, InP, SiC, and various other materials.

Key Features and Benefits

- Advanced ICP source enables highly uniform, high selectivity, and precise etching

- 2 kW RF power can be applied efficiently and stably

- ESC and He backside cooling for optimum temperature control

- The high flow exhaust system directly connected to the reaction chamber

- Compatible with ø2", 3", and 4" wafers

- In-situ end-pointing using interferometric and/or optical emission spectroscopic endpoint monitors

- Fast-switching gas input for ALE process as an option

Applications

- InP ridge etch for edge emitting laser

- InP DFB grating etch

- GaAs/AlGaAs mesa etch for VCSELs

- High selectivity etch of GaN/AlGaN

- GaN recess etch

- SiC/GaN trench etch for power electronics

- GaSb/InSb etch for NIR/SWIR sensors

- SiO2 and SiNx etch

- Al, Cr, Ni etch

Options

- Interferometric endpoint monitor

- Optical emission spectroscopy (OES) endpoint monitor

- Fast-switching gas line for ALE process