Plasma Cleaner PC-2000

Description

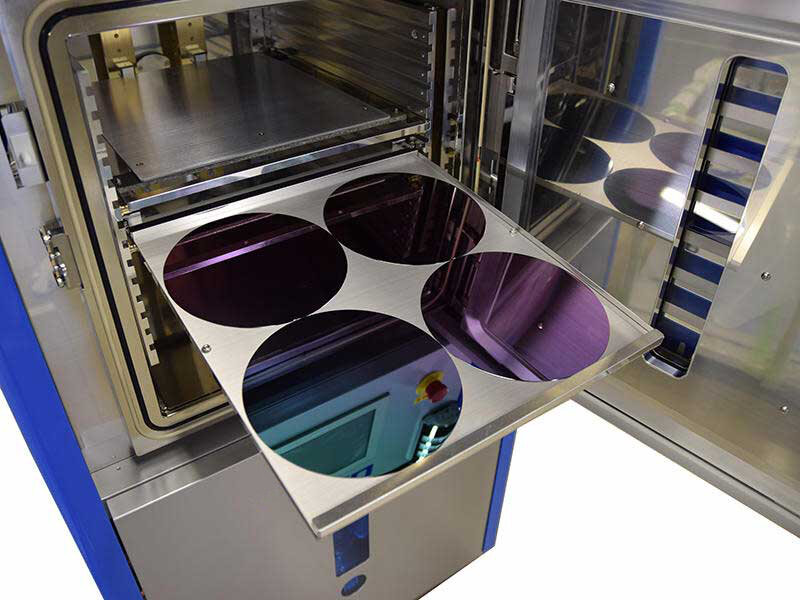

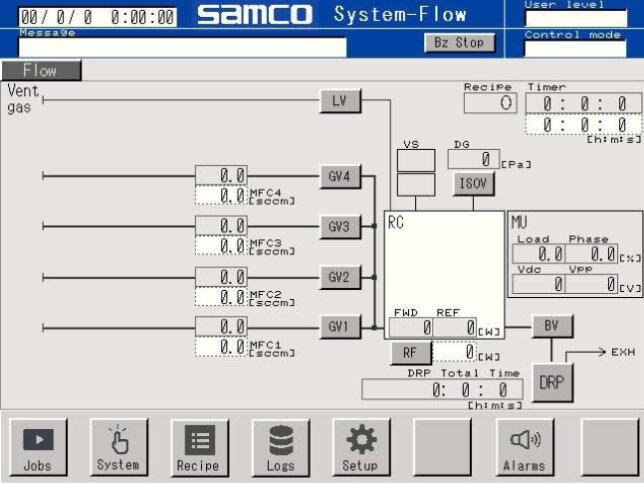

The PC-2000 is a parallel-plate plasma cleaner designed for dry cleaning and surface modification of semiconductor packaging substrates, optical components, and biomedical products. It offers two options for processing modes, plasma etching (PE), or reactive ion etching (RIE), which allows for optimal treatment tailored to the specific substrate type and application. The system's reaction chamber can accommodate multiple electrode shelves, enabling the simultaneous processing of a variety of components, from small parts to large square substrates. Additionally, the PC-2000 is equipped with recipe management and user-level switching capabilities, making it suitable for a wide range of applications, from research to high-volume production.

Key Features and Benefits

- Process mode selection (PE, RIE) for optimal, device-specific processing.

- Flexible shelf electrode allows processing of a wide variety of samples in either RIE or Plasma Etching mode.

- Protective plate and O-ring seals ensure easy cleaning and maintenance.

- RF power utilization up to 900 W enhances productivity.

- Large 10.4-inch touch screen for simple and intuitive operation.

- Added Vdc, Vpp, matching position display, and event logging functions.

- Internally installed dry pump allows for significant reduction in footprint.

Applications

- Cleaning and surface modification of plastic packages such as BGA and CSP, and lead frames

- Hydrophilization of optical components and molds

- Photoresist ashing, stripping, and descumming

- DLC film stripping for mold refurbishment

- Surface modification and hydrophilization of microfluidics, cell culture dishes, and more

Options

- Allows for up to 3-stage processing with the addition of extra electrode shelves

- PC-based data logging capability

- Slow exhaust/Slow vent valve