Anisotropic deep silicon etching technologies are divided into two groups. Number one is the Bosch process, a multi-step Si DRIE process that alternates between two steps, namely passivation layer deposition and isotropic silicon etching. Number two is a single step, non-Bosch Si DRIE process that simultaneously utilizes gasses for passivation layer deposition and etching.

The Bosch process can achieve high-speed etching, high selectivity over the photoresist masks, high aspect ratios and vertical etch profiles. In 2003, Samco became the first Japanese company to license the Bosch process from Robert Bosch GmbH to use for a wide range of applications that require high-aspect-ratio structure fabrication, such as inkjet heads, various types of sensors, healthcare, optical communications and biotechnology.

In 2003, Samco became the first Japanese company to license the Bosch process from Robert Bosch GmbH to use for a wide range of applications, such as inkjet heads, various types of sensors, healthcare, optical communications and biotechnology.

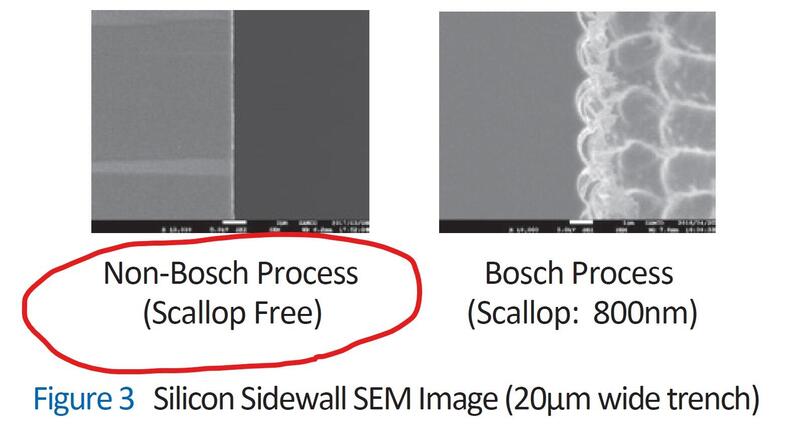

Although the Bosch process has the advantages of high etch selectivity and vertical profiles, smooth sidewalls are more challenging to achieve due to scallops formed during the cyclic deposition and isotropic etching processes. While scallop minimization is certainly possible with Bosch etching, to do so requires a comparatively slower etch rate. Non-Bosch Si DRIE, on the other hand, is capable of scallop-free and tapered structure fabrication because it's simultaneous etching and passivation ensures smooth sidewalls.

For that reason, depending on the process requirement of the etched profiles, there are cases when SF6/O2 non-Bosch DRIE is more appropriate than the Bosch process.

To continue, please submit the form.