Atomic Layer Deposition (ALD) is a technology to deposit thin films in the atomic scale, and it uses a chemical reaction between sample surfaces and precursors in sequential pulsing. Compared to conventional Plasma Enhanced Chemical Vapor Deposition (PECVD) technology, the deposition rate is slow, but conformal thin-film coating can be achieved on the trench and via hole structures in high aspect ratio. Furthermore, there is no physical and electrical damage, which is common in PECVD processes due to ion bombardment, on sample surfaces during ALD processes. Also, various types of thin films (oxides, fluorides, nitrides, metals, and more) can be formed by using a variety of precursor materials.

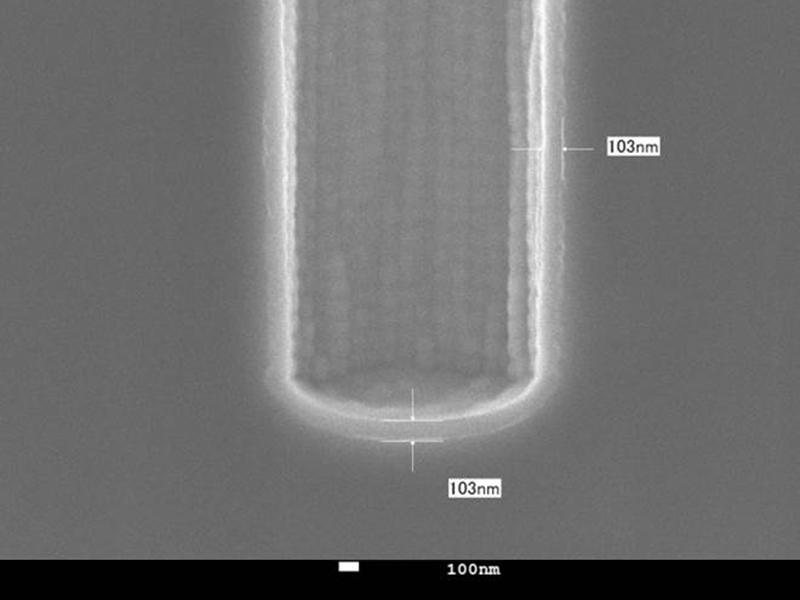

ALD-Al2O3 deposition

-

Products